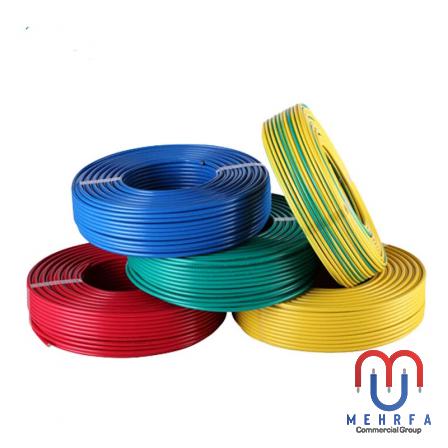

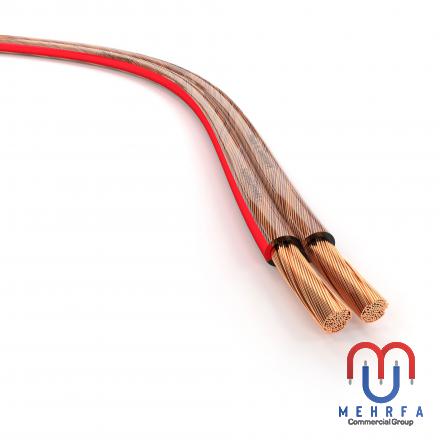

Non metallic sheathed cable exporters always do their best to conquer the domestic and foreign market. Buying a suitable power cable at a cheap price is one of the products that has a high supply throughout the country’s reputable stores and has attracted the attention of many people. These cables have a special application that you can easily buy them in the original quality and a reputable manufacturer and use the product in any type according to your needs.

What Increases the Flexibility of a Wire?

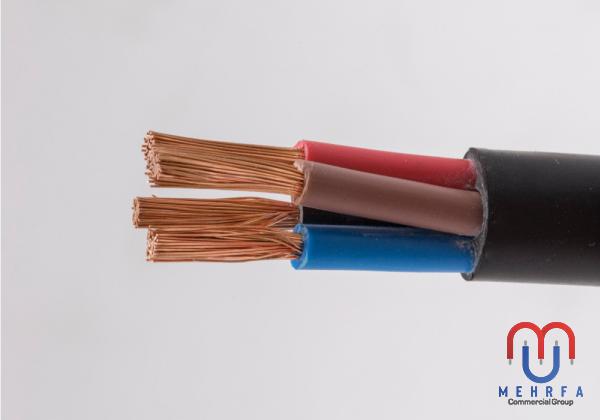

Flexibility coefficient is a key feature for stranded wires and industrial cables, especially aramid fiber strands. The flexibility coefficient of a fiber is the ratio of the stress on an axis to the elongation along the same axis. For example, think of stretching a plastic strap before it loses its original shape or breaks or tears. This is the issue of flexibility. When something is pulled to the point of losing its original shape, its strength decreases.

Flexibility coefficient is a key feature for stranded wires and industrial cables, especially aramid fiber strands. The flexibility coefficient of a fiber is the ratio of the stress on an axis to the elongation along the same axis. For example, think of stretching a plastic strap before it loses its original shape or breaks or tears. This is the issue of flexibility. When something is pulled to the point of losing its original shape, its strength decreases.

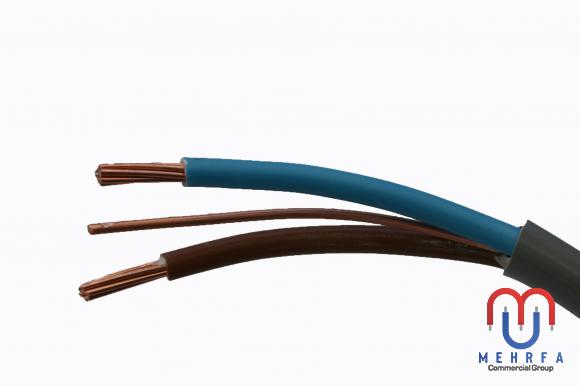

Elements of high flexibility are used in wires and cables to reduce the size and weight of the cable and increase its resistance to deformation. This makes it possible to apply more pressure to work with these wires and cables without fear of damage. Aramid fibers are widely used because they have excellent compositions with properties related to high flexibility, low density and low electrical resistance. Strength and flexibility are very important factors when the cable is located between the electric poles and is in contact with external elements that put extra pressure and tension on it.

Cable design requires the use of durable and strong materials. If you are making bulky cables, using a cable with a high flexibility and a short shear (polyester HMS) may be the best choice. If you are making a thin, lightweight cable for aerial use, using a high flexibility aramid combination is the best choice.

Continuous stability at different temperatures and different degrees of friction is another important factor in deciding on the best string with high flexibility to be used in wire and cable design. Tensile testing can help you test materials and determine the right degree of flexibility.

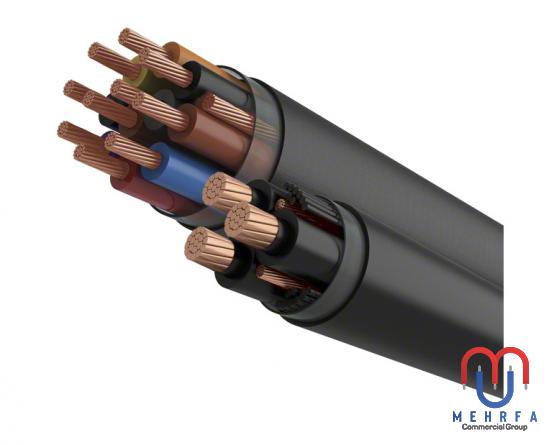

Sheathed cable distributors must consider all of the above in order to provide a higher quality product.

Non Metallic Sheathed Cable to Export

Non metallic sheathed is exported to different countries in Europe and Asia and its export contributes a lot to the prosperity and development of the country. These cables are suitable for the best production brands in the market for various electrical systems and have unparalleled sales.

Non metallic sheathed is exported to different countries in Europe and Asia and its export contributes a lot to the prosperity and development of the country. These cables are suitable for the best production brands in the market for various electrical systems and have unparalleled sales.

Non metallic sheathed cable are one of the best-selling cables that are produced in a very high amount annually and are sold directly and cheaply in the audio equipment store which can be easily found and purchased.

In general, non metallic sheathed cable price is usually variable and largely depends on its thickness.

Your comment submitted.